Why Describe Inteded Use and Consumer in Haccp Plan

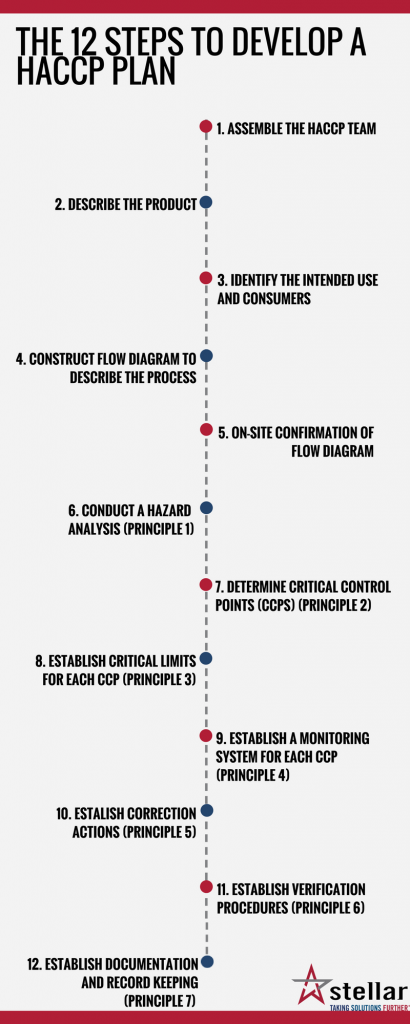

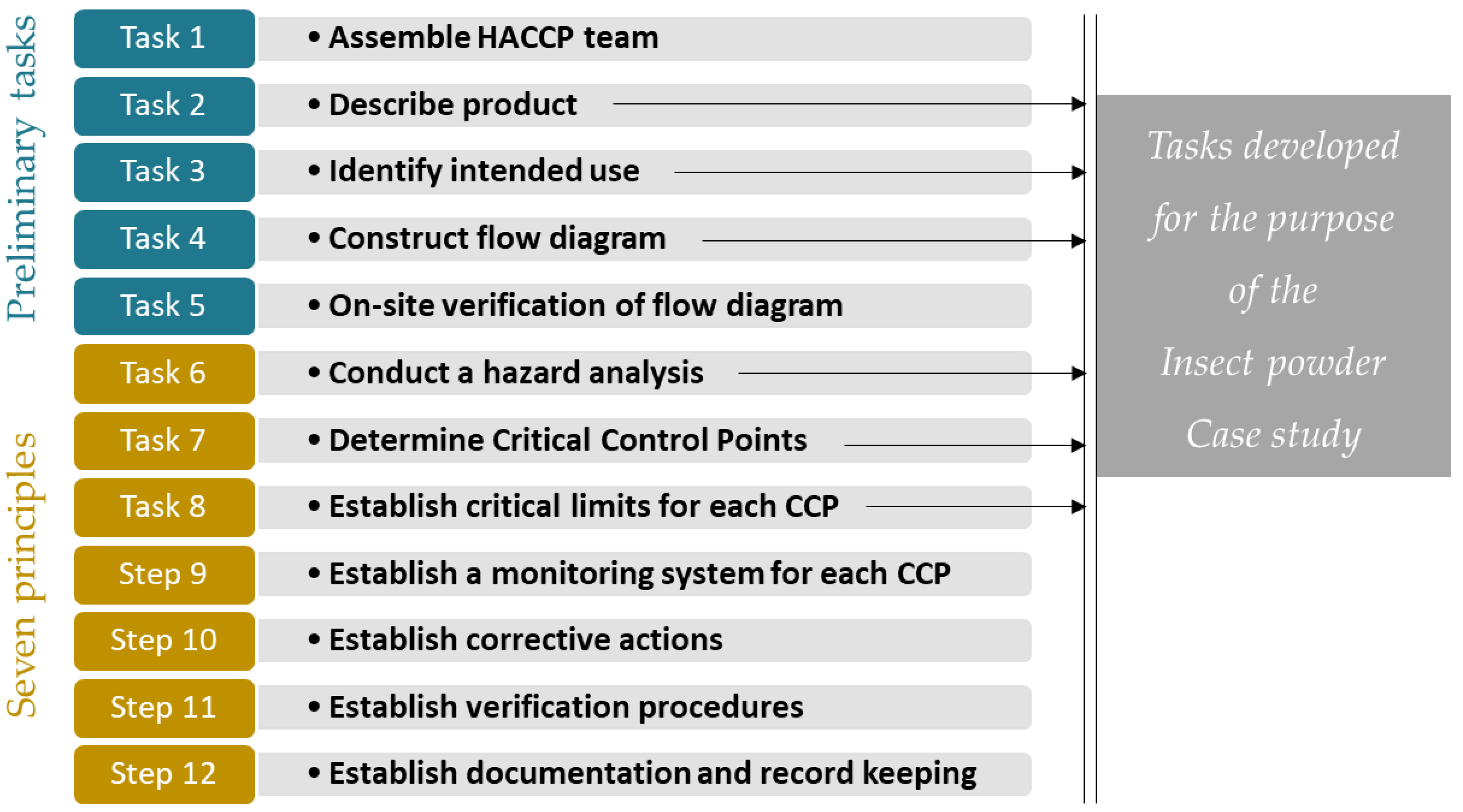

Assemble the HACCP team. Prerequisite programs such as current Good Manufacturing Practices cGMPs are an essential foundation for the development and implementation of successful HACCP plans.

Guidance For Industry Juice Hazard Analysis Critical Control Point Hazards And Controls Guidance First Edition Fda

Essentially a HACCP plan is needed to go about HACCP in the right way.

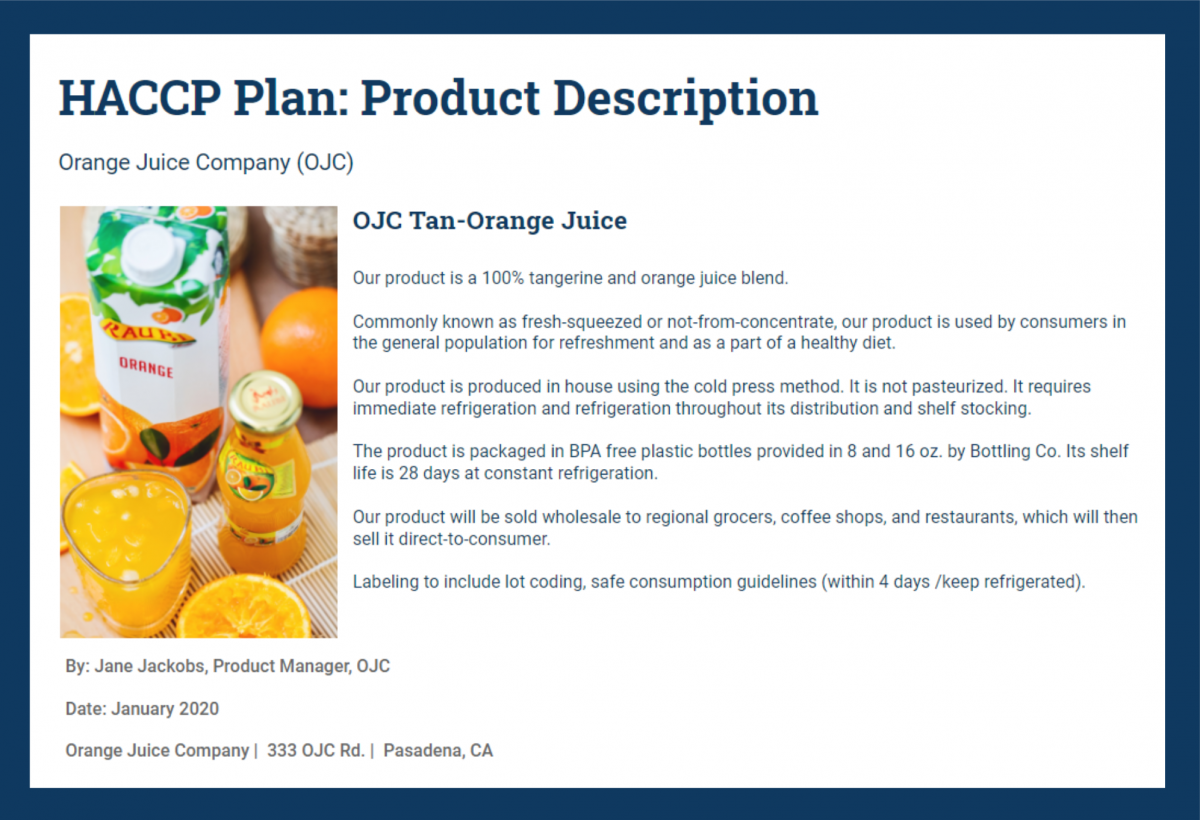

. Describe the intended use and consumers of the food. Describe the food and its distribution. Describe intended use and target consumers whether thats the public or a group such as infants.

Describe the food and its distribution. What is a HACCP plan. Designate a multidisciplinary HACCP team with employees from engineering production sanitation quality and microbiology.

Only listed usersconsumer Only listed uses Missing this step completely There are three major areas that need to be reviewed when determining the intended and unintended use of the finished product as well as the intended user. Activities that determine the validity of the HACCP plan and that the system is working according to the plan includes validation. As you can see from this article training is an essential piece to the puzzle when it comes to a successful food safety plan.

Would anyone have an example of one I. Since its inception in the 1960s as part of space travel the application of HACCP principles has expanded throughout the food industry. This page briefly introduces the concept of HACCP and its evolution into a Food Safety Plan.

A prevention food safety program developed for astronauts and applied to seafood and juice. HACCP plan is an internationally recognized procedure to identify and manage food and safety-related risks. Hi all I am working on a HACCP implementation project for a catering industry and i am new to this.

As a result of its initial success. It when it becomes a part of a food and safety program provides the customers regulatory authorities and the public certain assurances that tell the program is well-developed and carefully managed. Ad Learn The Requirements of HACCP And How To Write a HACCP Plan With Our 100 Online Course.

100 customizable HACCP plan. -describe the food and its distribution-develop intended use and consumers of the food-develop flow diagram-verify flow diagram. Hazard identification During this brainstorming session stage the HACCP team reviews the ingredients used in the product the activities conducted at each step and the equipment used the final product and its method of storage and distribution and the intended use and consumers.

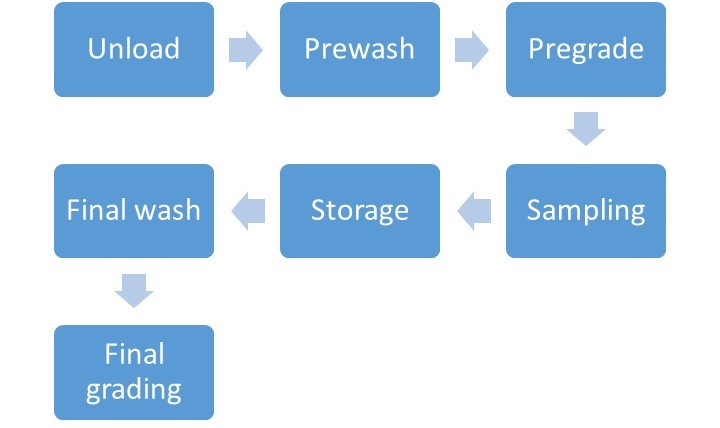

The article we link to describes how to use HACCP concepts to handle mycotoxins. Get qualified HACCP plan in 1 hour. Develop a flow diagram which describes the process.

Product description and intended use - posted in HACCP - Food Products Ingredients. Preliminary steps in developing a HACCP plan include. Identify intended use of the product This page is currently being updatedApologies for any inconveniences caused.

Ad You answer questions and we build you a HACCP plan. While HACCP is intended to reduce the risk of unsafe food products it can also have the benefit of leading to improved product quality. What is a HACCP Plan.

Its focus is on control and prevention throughout the food production process instead of reliance on finished product testing only. If you like many others need extra help with training your team or building your plan Safe Food Alliance is here to help. It is a science-based systematic approach and risk assessment tool designed to identify and assess specific hazards including chemical microbiological physical and now often radiological hazards.

Ready to serve product. Hazard Analysis Critical Control Points HACCP is an internationally recognized method of identifying and managing food safety related risk and when central to an active food safety program can provide your customers the public and regulatory agencies assurance that a food safety program is well managed. 16 days under proper.

The Hazard Analysis Critical Control Point HACCP is a management system used to control hazards related to food safety. Assemble the HACCP team including one person who is HACCP-trained. May also be used as an ingredient in preparing meals.

Product descriptions developed by manu-facturing personnel using the best avail-able information at the plant may radically differ from Marketings expectations. Describe the food including ingredients and processing methods as well as distribution methods and temperature requirements. While HACCP is an approach a HACCP plan sometimes referred to as a HACCP process document informs people of the necessary food safety-related procedures that should be followed to manage food safety hazards.

Describe the food and its method of production and distribution. The HACCP team need to have a thorough understanding of the intended use of the products included in the HACCP study so that they may undertake an accurate hazard evaluation as part of the Hazard Analysis. Speaking of which heres a free HACCP Plan.

A HACCP plan is a food safety monitoring system that is used to identify and control biological chemical and physical hazards within the storage transportation use preparation and sale of perishable goods. Consumers of all ages consume this product. These activities are best performed by Marketing and RD.

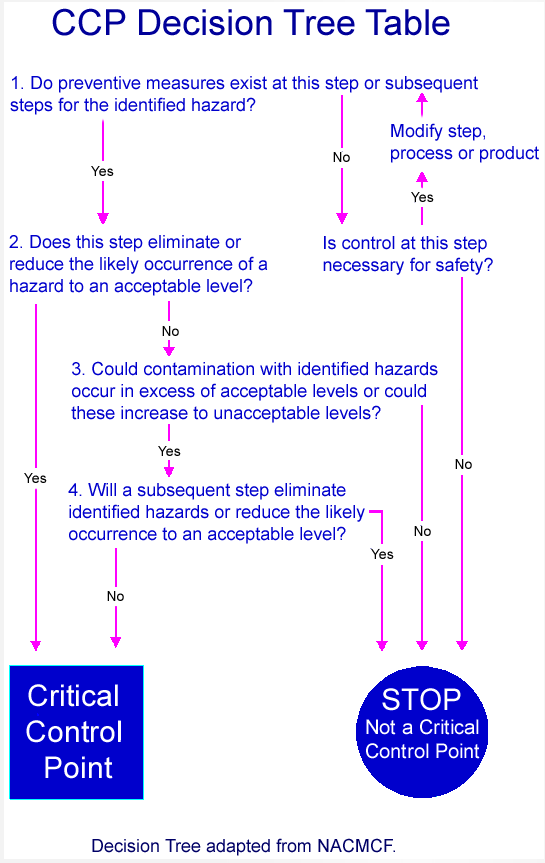

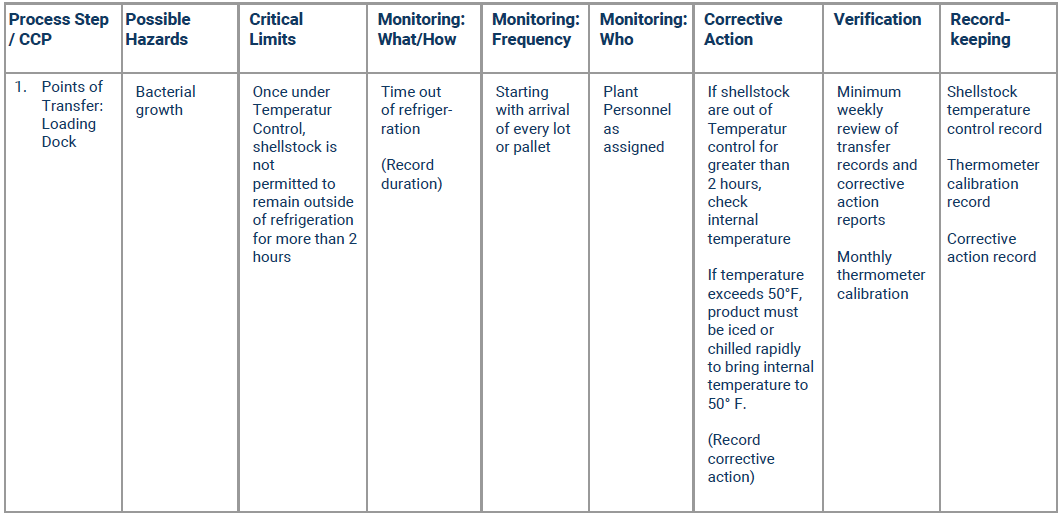

It requires participants to analyze and control the biological chemical and physical hazards at all points of production from raw material production to consumption. The Food Safety Modernization Act December 2010 is expected to lead to further adoption of the concept. It also determines critical control points CCP in the process of food production.

Could any one tell me if there is a specific template for the preliminary steps 2 and 3 ie description of product and identify intended use. Describe the intended use and consumers of. Digital HACCP consultant is there for you 247.

For example a plants HACCP team may. Conduct a Hazard Analysis. Of intended use and the identification of the target consumer.

The Hazard Analysis Critical Control Point. The areas are 1 RTE status of food 2 Intended use 3 Consumer use. The activities that determine the validity of the HACCP plan and that the system is operating according to the plan.

Based on this review the team develops a list of potential biological. HACCP is designed for use in all segments of the food industry from growing harvesting processing manufacturing distributing and merchandising to preparing food for consumption.

Product Description And Intended Use Download Table

Haccp Plan Template How To Write A Haccp Plan Image Search Results Food Safety Hygienic Food Reality Quotes

Good Hygiene Practices Along The Coffee Chain Describe Product And Identify Intended Use Tasks 2 3 Module Ppt Download

How To Plan And Manage A Successful Haccp System Safesite

The 12 Steps To Develop A Haccp Plan Stellar Food For Thought

Steps In Developing And Haccp Plan Download Table

Haccp Plan Template Forms Checklist Report Safetyculture

Haccp Product Description And Intended Use Checklist Safetyculture

Foods Free Full Text Control Of Biological Hazards In Insect Processing Application Of Haccp Method For Yellow Mealworm Tenebrio Molitor Powders Html

Section 3 The Hazard Analysis And Critical Control Point Haccp System

Product Description And Intended Use Download Table

The Beginners Guide To Haccp Safe Food Alliance

Section 3 The Hazard Analysis And Critical Control Point Haccp System

Hazard Analysis And Critical Control Point Haccp System And Guidelines For Its Application

Comments

Post a Comment